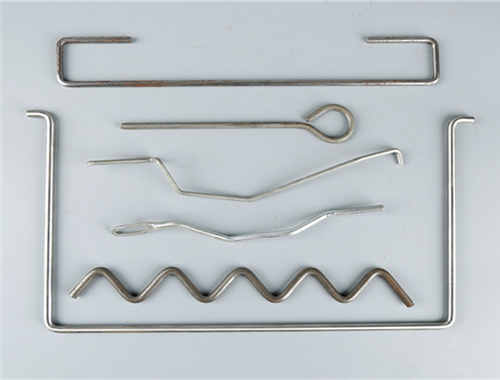

It is a full automatic wire bending machine controlled by industrial computer, the design of which mainly aims at forming & processing of medium batch and large batch of wire and settling the instable conditions of manual processing. Additionally, it can greatly reduce switching time and quantity of waste products, and can switch products at real time under the conditions of same wire diameter and existing program.

The bending method is to adopt the computer to switch the twist-aided rotary core with different external diameter and control the rotation angle of twist head and then cooperate with the wire feeding in order to meet the requirement of bending different angle and diameter; therefore, it needs no specialized or complicated mould for forming which greatly reduces the time and cost required by developing new product.

Processing wire diameter: 1.2 - 6mm & 1.2 - 10mm & 1.2 - 13mm

Max.Feeding speed (m/min) | 50 |

0.2 | |

Min.time required to reverse the core conversion (s) | 0.2 |

Min.time required to turn line 90 ° (s) | 0.8 |

Max. Speed reverse mechanism (mm/s) | 250 |

Largest feed limit | Unlimited |

Feeding way | Roller wire |

Bending speed | |

Feeding speed | 900mm/1.0s |

Input data style | Data/teaching |

Bending servo motor power | 3000w |

Feeding servo motor power | 3000w |

Electric capacity (KVA) | 15 |

Weight (KGS) | 3000 |

The main machine external dimensions (mm) | 3500*1650*1600 |

The auto feeder external dimensions (mm) | 1800*1800*1500 |